- Quickly to oisd 118 standard pdf carry notes on ward rounds. UPDATED VERSION APRIL 2012 click on image to download PDF file However. Hopefully it may serve as a guide for your Orthopedic posting. However, most of the notes are based on one minute millionaire free pdf my experience while working in. Click on image to download PDF file.

- .Oil Industries Safety Directorate (OISD), India OISD 141 OISD 214 OISD 118 Design and construction Documents OISD STANDARD - RP-164 - OILWEB - Corporate Intranet view1999-02-04OISD - STD-164.

Download >> Download Oisd 118 latest edition pdf

Read Online >> Read Online Oisd 118 latest edition pdf

Download grab app.

STORAGE AND HANDLING OF PETROLEUM PRODUCTS AT DEPOTS AND TERMINALS Prepared by FUNCTIONAL COMMITTEE OIL INDUSTRY SAFETY DIRECTORATE GOVERNMENT OF INDIA MINISTRY OF.

Oisd 154 Pdf

oisd - std - 113 first edition for restricted circulation only classification of areas for electrical installations at oisd 118. oisd 117. list oisd. oisd 170 Latest Events/OISD Activities: Latest OISD Standards October 2017 Edition released OISD Activities Report 2015-16 OISD STANDARD - 116 Second Edition, have been made to incorporate the latest technological changes, FIRE PROTECTION FACILITIES FOR PETROLEUM REFINERIES OISD STD-118 - Download as Word Doc (.doc), PDF File (.pdf), OISD-STD-118 Revision New Delhi Amended Edition As per OISD-STD-118, petroleum storage tank shall be located in dyked enclosure with roads all around the enclosure. Now our products are Class C i.e. excluded Download >> Download Oisd 144 pdf Read Online >> Read Online Oisd 144 pdf oisd 169 pdf oisd latest and comply with the OISD OISD STD 105, 116, 117, 118 Oisd standard 116 pdf Layout of an installation shall be done in accordance with OISD-Standard-118 on (2004 Edition) and the latest'. PDF OISD 144 and OISD 169 Volume 1 Design Criteria. PDF . OISD 144 and OISD 169 Volume 1 Design Criteria. Notify me of new comments via email. SPECIFICATIONS FOR TANK FABRICATION . CONTENTS (latest Edition). OISD-118 : Oisd standards free LIST OF OISD cross country hydrocarbon pipelines oisd-std-141 first edition, Directorate Download Latest Oisd Standards PDF API 526 (Flanged Steel Pressure Relief Valves) - PDF Showing 1-1 of 1 messages API 526 (Flanged Steel Pressure Relief Valves) - PDF Showing 1-1 of 1 messages MINISTRY OF PETROLEMUM & NATURAL GAS Notification New Delhi, the 13th march, 2002 OISD -105, OISD-116, OISD- 117, OISD-118, OISD-141 and OISD -156; (b) the additional requirements shall be applicable to all new locations conceived after publication of the new edition STD-118 & OISD -STD-109 as OISD Oisd std 118 liquefied petroleum [pdf document], oisd std 113 first edition for restricted is intended to be the 'latest revisions. Oisd 113 pdf

Oisd 116 Pdf

, C1815 transistor datasheet pdf, Fiasco the inside story of a wall street trader pdf, Ge optima xr220amx service manual, Kamasutra book pdf in urdu with photos.

OISD Standards List - Oil Industry Safety Directorate (OISD)

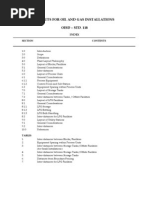

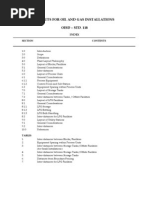

OISD-STD-118 Revision - IIFOR RESTRICTED CIRCULATION LAYOUTS FOR OIL AND GAS INSTALLATIONS OISD – STANDARD – 118 Revision – II, September 2004 Oil Industry Safety Directorate Government of India Ministry of Petroleum & Natural Gas OISD-STD-118 Revision – II September 2004 FOR RESTRICTED CIRCULATION LAYOUTS FOR OIL AND GAS INSTALLATIONS Prepared by Committee on Layouts for Oil and Gas Installations OIL INDUSTRY SAFETY DIRECTORATE 7TH FLOOR, NEW DELHI HOUSE 27, BARAKHAMBA ROAD NEW DELHI – 110 001 NOTE OISD Publications are prepared for the use in the Oil and Gas Industry under the Ministry of Petroleum & Natural Gas. (ii) . Though every effort has been made to assure the accuracy and reliability of the data contained in these documents. These are the property of Ministry of Petroleum & Natural Gas and shall not be reproduced or copied or loaned or exhibited to others without written consent from OISD. OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from their use. These documents are intended to supplement rather than replace the prevailing statutory requirements. Barakhamba Road New Delhi-110 001 (iii) . It is hoped that the provision of this document. coupled with feed back from some serious accidents that occurred in the recent past in India and abroad. operating and maintaining oil and gas installations. will go a long way in improving the safety in oil and gas industry. Oil Industry Safety Directorate (OISD) was established in 1986 staffed from within the industry in formulating and implementing a series of self regulatory measures aimed at removing obsolescence. This document will be reviewed periodically for improvements based on the experience and better understanding. With this in view. experience gained after the implementation of standards and relevant updation in the various national and international codes and practices. if implemented objectively.FOREWORD Oil Industry in India is over 100 years old. The original document on 'Layouts for Oil and Gas Installations' was published in November 1988 and its first revision released in July 1995. emphasised the need for the industry to review the existing state-of-the-art in designing. As such variety of practices have been in vogue because of collaboration / association with different foreign companies and governments. In August 2000 it was amended inline with the recommendations of the High Power Committee. This. The present document on “Layouts for Oil and Gas Installation” is the second revision of this OISD Standard. Suggestions from industry members may be addressed to: The Coordinator Committee on Layouts for Oil and Gas Installation Oil Industry Safety Directorate 7th Floor. Standardization in design philosophies and operating & maintenance practices at national level was hardly in existence. Accordingly. standardising and upgrading the existing standards to ensure safer operations. Attempts have been made to incorporate the latest technological changes. New Delhi House 27. OISD constituted number of functional committees comprising experts nominated from the industry to draw up standards and guidelines on various subjects. COMMITTEES ON LAYOUTS FOR OIL AND GAS INSTALLATIONS First Edition – November 1988 Leader Shri R P Bhatia Members Shri K K Arora Shri S K Mukherjee Shri V K Raina Shri K Ravi Kumar Member Coordinator Shri B K Trehan Oil Industry Safety Directorate. New Delhi First Revision – July 1995 Leader Shri R P Bhatia / Shri M M Kapur (Feb 95 – July 95) Members Shri S K Mukherjee Shri K K Arora Shri V K Raina Shri S Pandarinathan Member Coordinator Shri B Sadhukhan / Oil Industry Safety Directorate. Shri S N Mathur (April 95 – July95) Hindustan Petroleum Corporation Ltd. Madras Refineries Limited. Bombay. Bombay. Madras. New Delhi Amended Edition – August 2000 Amendments were carried out to this standard based on the recommendation of High Power Committee set up in 1997 by the Ministry of Petroleum and Natural gas to review the standard with respect to land requirement inline with national and international standards. Oil and Natural Gas Corporation Ltd. (M).. Bombay. Bharat Petroleum Corporation Ltd. Bombay. Engineers India Limited.(R) Bombay Bharat Petroleum Corporation Ltd. Hindustan Petroleum Corporation Ltd. (iv) . Engineers India Limited. Madras Refineries Limited. Madras. (M).(R) Bombay Oil and Natural Gas Corporation Ltd. T. Shri Thomas Chacko. Shri S. Shri K.Banerjee Shri M. Shri D.Palnitkar. Rao. New Delhi BPCL. Shri A.Maji.Lokhande.D. (v) . NOIDA IOCL. Visakhapatnam. IOCL Pipelines Division. review and finalization of this document. New Delhi In addition to the above. several other experts from the industry contributed in the preparation.S. Panipat IOCL Refineries HQ. Panipat Refinery. Duliajan MEMBER-CO-ORDINATOR S K Aggarwal Oil Industry Safety Directorate.Shah Shri S. Shri Sunil Dewan. Mumbai Refinery.S. Shri H.COMMITTEES ON LAYOUTS FOR OIL AND GAS INSTALLATIONS Second Revision – Month /Year LEADER Shri Vinay Kumar MEMBERS GAIL (India) Limited. Kochi HPCL Visakh Refinery. Engineers India Limited. New Delhi Department of Explosives.P.G. Mumbai Kochi Refineries Limited. Nagpur BPCL.Buragohain. New Delhi Shri Arvind Kumar.K. NOIDA Oil India Limited. 0 6. Separation distances between Blocks / Facilities Separation distances between equipment within Process unit Inter-distances between Storage Tanks and Offsite facilities (Large installation) Separation distances between Storage Tanks and Offsite facilities (Small Installations) Separation distances between Storage Tanks within a Dyke Separation distances for LPG Facilities Separation distances between LPG Storage Vessels and Boundary / Property line / Group of Buildings not associated with LPG facilities (vi) . T4.0 4. T2. T7.0 5.0 8. T3.INDEX SECTION CONTENTS PAGE No.0 9. 1. T5.0 3.0 Introduction Scope Definitions Plant Layout Philosophy Layout of Blocks/Facilities Layout of Process Units Layout of Storage Tanks Layout of LPG Facilities References TABLES T1. T6.0 7.0 2. flare etc. The minimum distances recommended many years ago need review in the context of today's environment in the industry. For these reasons. communication and alarm system. group of pressurized storage tanks. loading gantries. Tank farm for storage of crude / products. LPG. Propane.' . transportation and distribution. treating or storing crude oil and includes central tank farm. c) Crude Oil Gathering Station: Crude oil gathering station / Group gathering station is a production installation used for gathering. Lube oil installations and other Petroleum storage installations such as Crude oil gathering stations. Today's trend of large and complex plants present substantial risk potential. e) d) 3. group of tanks located in a dyke. Fire station A building housing facilities of parking fire tenders and keeping other ready to use fire-fighting equipment for meeting plant emergencies. structure. it may not be practicable to comply with. Examples are Butane. boiler house. At times plants are modified to operate at higher capacities or efficiencies necessitating larger storage requirements than contemplated earlier. a mixture of propane and butane also fall under the same category. LPG facilities. oil collecting station. jockey pumps. The requirement of green belt / buffer zone beyond the plant boundary is outside the scope of this standard. It is not intended that requirement of this standard should be applied rigidly to existing premises where. For example process unit. or other physical feature used in petroleum refining. gas compressor station and well head installation.0 SCOPE This document lays down minimum requirements of layouts within the plant boundary for petroleum refineries. instrumentation and the required operating & supporting personnel.0 INTRODUCTION Hydrocarbon processing and handling plants are inherently hazardous.0 a) DEFINITIONS Block Facilities operated / used in integrated way and surrounded by roads.OISD-STD-118 1 -------------------------------------------------------------------------------------------------------------------------------------- LAYOUTS FOR OIL AND GAS INSTALLATIONS 1. equipment. The hydrocarbon industry over the years learnt lessons from fires and explosions throughout the world and has been updating plant safety norms including inter-distances between facilities and their relative locations. Oil / Gas production and processing plants. 2. C4 and Lighter ends Hydrocarbons or a mixture of Hydrocarbons containing four or less than four carbon atoms. Such provisions should be considered based on local environmental / security requirements. f) Fire Water pump house A building housing fire water pumps. fire control room with required communication facilities/mimic panel. g) Flash Point 'Flash point' of any petroleum liquid is the lowest temperature at which the liquid yields vapour in sufficient concentration to form an ignitable mixture with air and gives a momentary 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. Facility This refers to any building. pipeline. storage. installation. initial site analysis for the proposed new construction or addition should be done carefully while considering the space allocation to the various facilities. for a variety of reasons. Propylene etc. Aviation storage & fuelling stations. Pipeline installations / terminals. Marketing depots and terminals. May Indicates provisions that are optional.C is likely to be refined. blended or stored at above its flash point. stabilized and despatched for further processing. Lube Oil Installations The facilities for receipt.C or any flammable gas or vapor in a concentration capable of ignition is likely to be present. p) Petroleum Refinery Petroleum Refinery is a plant where crude oil is received and processed into intermediates and finished products. and may involve preparation. q) Process Unit A unit having integrated sequence of operation. Liquefied gases including LPG do not fall under this classification but form separate category. j) Hazardous Area An area will be deemed to be hazardous where. r) Protection for exposure This refers to fire protection for structures on property adjacent to liquid storage. For classification and extent of hazardous area. received / despatched by rail / road / pipeline and / or filled in cylinders. grease manufacturing plants.OISD-STD-118 2 -------------------------------------------------------------------------------------------------------------------------------------- flash on application of a small pilot flame under specified conditions of test as per IS: 1448 (Part-I). storage and blending of base oils & additives into finished Lube products. (i) Petroleum having flash point below 65 deg. intermediate pumping station / compressor station. s) Service building A building housing facilities for inspection / maintenance / other 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. or change in state. Note: In the following cases. above classification does not apply and special precautions should be taken as required: o) Pipeline Installations Pipeline Installations are the facilities on cross-country pipelines and include sectionalizing valve station. i) General Classification Of Petroleum Products Petroleum products are classified according to their closed cup FLASH POINTS as given below: l) — Class-A Petroleum: Liquids which have flash point below 23oC. (ii) Where product handled is artificially heated to a temperature above its flash point. refer 'The Petroleum Rules . (i) Where ambient temperatures or the handling temperatures are higher than the flash point of the product. tap-off station. It includes lubeblending plants. Drilling activities and facilities upstream of the Christmas Tree of a well are not covered under this definition. LPG. — — Class-C Petroleum: Liquids which have flash point of 65 oC and above but below 93 oC.2002'. Excluded Petroleum: Liquids which have flash point of 93 oC and above. condensate etc. Oil / Gas Production Plant Oil / Gas production plant is a plant where oil and/or gas is collected. h) k) LPG Facilities LPG facility is one where liquefied petroleum gas (LPG) is stored. m) n) — Class-B Petroleum: Liquids which have flash point of 23 oC and above but below 65 oC.' . separation. physical and chemical. Gas Processing Plant Gas processing plant is a facility where natural gas is received and processed to separate gas. energy content or composition. (ii) Petroleum or any flammable liquid having flash point above 65 deg. pig launching / receiving station. dispatch and receiving facilities with or without storage. purification. g. gradient and turning radii at road junctions shall be designed to facilitate movement of the largest firefighting vehicle in the event of emergency. 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. Shall Indicates provisions that are mandatory. f) Road widths. For floating roof tanks. h) Layout of the facilities shall be made to minimise truck traffic ingress in the plant. workshop etc. and (d) company philosophy. it is the height from tank bottom to top of tank shell. Plant layout arrangement should follow the general route of raw material to process unit(s) with tankages interposed as required followed by storage & despatch facilities. (c) company experience. (b) company standards. fired equipment etc should be located in such an area so to facilitate erection. g) Rail spur shall be located close to the periphery of the plant to minimise road/pipe crossings and blockage of roads during shunting. x) Tank height Tank height is the height from tank bottom to top kerb angle for cone roof tanks. d) e) Pedestrian pathways should be provided / marked alongside the primary traffic roads. n) For construction activities. The entire area should be sub-divided into blocks. reactors. 4. as appropriate: (a) risk / benefit analysis. Towers. furnaces & Block layout should be adopted as far as possible. heaters. warehouse. y) Tank vehicle loading / unloading Facility for loading / unloading of petroleum product to / from tank wagon or tank truck. Presence of ignition source shall always be contemplated beyond the boundary wall of the installation. Roads separating the blocks shall act as firebreaks. Both these approaches should be available for receipt of assistance in emergency. j) k) Orientation of flares. Implementation of these provisions shall be made based upon consideration of the followings.0 PLANT LAYOUT PHILOSOPHY Following philosophy should be adopted in layout of an installation. Alternative access shall be provided for each facility so that it can be approached for fire fighting in the event of blockage on one route. All process units and dyked enclosures of storage tanks shall be planned in separate blocks with roads all around for access and safety.OISD-STD-118 3 -------------------------------------------------------------------------------------------------------------------------------------- supporting services which are directly required for operation of the plant e. Erection methods shall be studied for all types of equipment / structures. dusty operations (e. i) t) u) Should Indicates provisions that are recommended but not mandatory. Primary traffic roads in the installation should be outside hazardous areas.g. area should be earmarked. l) b) c) m) Maintenance requirements for each type of equipment shall be identified and considered. v) Stabling Line It is an additional railway line / spur reserved for additional rake / stabling.' . sulphur handling etc) and cooling towers should be decided based on prevailing wind direction to avoid travel of hydrocarbon vapour over sources of ignition. a) Two road approaches from the highway / major road should be provided. w) Storage / filling shed Facility for storage and filling of packed (non-bulk) petroleum product. one for employees and other for product / material movement. Chemical / Toxic chemicals storage. fire station and fire training ground . the following should be considered: (a) Layout of Blocks / facilities should be in sequential order of process flow. as applicable. information should be collected on the following aspects. refer OISD-STD-163. (i) Low Tension (LT) sub-station should be located at load centers in such a way that the distance between distribution transformer and farthest motor is minimum.Risk to and from adjacent facilities .Statutory obligations 5. hazardous waste storage / disposal. For details. (f) Power generation facilities which also supply steam for process requirement should be located near the process unit block. . storage tanks. Horizontal clearance shall be in line with the Indian Electricity Rules. then it may be considered as a single block. tank farm. loading space provision be made accordingly. It shall not be located on a lower level than surrounding plants and tank farms. petroleum wax. storage areas for solid products such as petroleum coke. (h) High Tension (HT) sub-station(s) should be located close to major load centers. . (d) Control room should be located in a non-hazardous area upwind of process plants / hydrocarbon storage and handling facilities. (e) Utility block(s) should preferably be located adjacent to unit blocks.) for installations in coastal areas. utilities. To prepare a layout. natural streams/ canals . water table.Service buildings.Site topography including elevation. bitumen / asphalt etc and other open storage areas like scrap yards and dumping ground . 5. road and pipeline) . LPG storage vessels and other pressurized storage vessels . Effluent Treatment Plant (ETP) and approach roads should be located on high ground to avoid flooding. utility requirements. sulfur. solid storage. In undulating areas.OISD-STD-118 4 -------------------------------------------------------------------------------------------------------------------------------------o) Future expansion should be assessed and (b) Process unit(s). and drainage . surge wave height etc. (g) Overhead power transmission lines shall not pass over the installation including the parking areas. Cooling Towers should be located downwind of process equipment and substation so that fog developed will not cause corrosion or obstruct vision or short-circuiting.' .Meteorological data. When external power grid is interconnected with plant power generation facilities.Approach roads to main plant areas . .Seismic data .Warehouses. LAYOUT FACILITIES OF BLOCKS / gantry.Bathymetric data (high tide level. (c) In case process units are operated in an integrated way and shutdowns are taken simultaneously. . There shall be no structure that would fall on the control room in case of a blast.Flares . slope. (j) (k) Storage tanks should be grouped according to product classification.Environmental considerations .0.Highest flood level in the area. storage tanks should be located at lower elevations (l) Truck loading / unloading facilities should be located close to product movement gate and should be oriented 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.1 General consideration for the layout of blocks / facilities While locating the various facilities / blocks.Process units. either the power plant should be located at the side of the boundary wall or the external power transmission lines should be taken underground upto interconnection grid.Aviation considerations .Product receipt / despatch and mode of transport (rail. operability.0 LAYOUT OF PROCESS UNITS Equipment in process unit can be arranged in many ways. Smoking booths should not be provided in the hydrocarbon industry. These roads should encircle the process blocks/ process units. However if required. Safety. Heat Exchangers and vessels should be grouped together forming outer rows on both sides of the rack. Flare should be located upwind of process units and the area around flare should be paved. down wind of process units and important areas considering odour & emission of volatile organic compound. Fire station should be upwind of process units and hydrocarbon storage area with straight approach to process units / other critical areas. hazardous and populated areas. air separation plants. This should be closer to disposal point by the side of the boundary and at lower grade to facilitate gravity flow of effluent. OISD-STD-117 & OISD-STD-144 as the case may be. maintenance and fire fighting. Spacing between equipment shall be adequate for undertaking maintenance jobs. Main pipe racks / pipe track shall not be routed through process units. populated and hazardous areas.g. (n) Petroleum coke storage and handling facilities should be located as far as possible away from process units. Rail loading facilities should be located along the periphery of the installation. Equipment drawing air (e. Minimum separation distance of 50 meters is recommended between sulfur storage / handling and any facility or boundary wall. firewater storage & firewater pump house shall be located at a safe place away from hazardous areas. For more details OISD-STD-106 on 'Process Design and Operating Philosophies on Relief and Disposal systems' shall be referred. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. located at minimum distance of 60 meters from any hydrocarbon source. The table shall be read in conjunction with the notes specified with the table. 6. (o) 6. acid effluents. Adequate spacing between equipment will help in minimizing the spread of fire. (b) The unit pipe rack should be kept in the centre. Consideration should be given to access for fire fighting. (u) 5. Location of firewater pumps & tanks shall be inline with OISD-STD116.2 Separation distances.1 (p) General Considerations for the layout of Process Equipment (q) (r) (a) Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. economy. Provide overhead clearance for vehicles over roadways and railroads. and ease of maintenance should be considered in locating each item within the unit.OISD-STD-118 5 -------------------------------------------------------------------------------------------------------------------------------------- to provide one-way traffic pattern for entrance and exit. Minimum separation distances between various blocks / facilities described above shall be as per Table-1. (m) Sulphur recovery unit and sulphur loading area should be located close to product movement gate and away from process units. air compressors. these shall be (t) Fire station. FD fan etc) should be located away from Sulfur recovery unit / Sulfur handling facility. Roads should be provided in a symmetric manner to serve all process areas requiring access for the operation. air blower. caustic. Effluent Treatment Plant should be located minimum one block away from process unit area. Pumps may be arranged in two rows close to and on either side of the pipe rack. thereby splitting the unit into two or more areas of equipment. (s) 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. fecal etc. Separate collection system should be provided for different types of waste generated in the process plant such as oily water.' . Hydrocarbons day tanks shall be provided with dyke in line section 7. column. pipes. (q) Blow down facilities / buried drum should be located at one corner of the plant farthest from furnace or any fired equipment and on the lee-ward side of the unit. (f) Towers / columns should be located along the pipe rack towards open areas for unobstructed erection as well as maintenance of internals at grade. (j) No trenches or pits which might hold flammables should extend under the furnace and connections with underground drain system should be sealed over an area 15 meters from the furnace walls. (l) Gas compressors should be located down wind from heaters so that leaked gases will not drift towards the heater. (h) Vessels. Vent from Blow down facility shall be minimum 6m above the highest equipment falling with in radius of 15 m from the vent stack. (t) Minimum headroom under vessels.' .1 meters. these should be located in open area. Forced Draft fans shall be located away from process equipment from where they are likely to suck hydrocarbon vapors. chemicals etc should have a drop-out area for removing / installing the internals and / or for loading / unloading of catalysts and chemicals.OISD-STD-118 6 -------------------------------------------------------------------------------------------------------------------------------------- (c) Heat exchangers should be located perpendicular to the pipe rack on the outer row to facilitate pulling of tube bundles with mobile crane or by other means. cable racks. (m) No other tankage except day tanks / process chemicals shall be provided within battery limits of any process unit. Shell and tube heat exchanger should have a longitudinal clearance of at least one-meter plus the length of removable bundles. etc should be 2. (d) Air fin coolers should be installed above the pipe rack / technological structures / independent structure. Where process requirement dictates their installation above grade. (k) The local control panel for soot blower control and flue gas analyzer only should be located on and near the process heater. (g) Thermo-siphon reboilers should preferably be placed close to their associated towers. (o) Cold boxes should be located on grade or on separate elevated structures. (e) Vessels having large liquid hold-up should be installed at lower heights and preferably at grade. (i) Heaters should be located up wind at one corner of the unit. (n) Process chemicals storage tanks should be provided with kerb wall of minimum 300-mm height. (p) Flare knock out drum for the process units should be located at battery limit of the unit. Reactors with internals and / or containing catalysts. The cabin should be located upwind side of the unit in nonhazardous area and away from draining / sampling facilities. Drop out area should be provided for maintenance. Adequate space should be provided around cold boxes for ease of operation and maintenance. (r) Operators cabin may be provided in the process unit. 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. Space should be provided for removal and cleaning of heater tubes besides approach for crane. Areas around the heaters shall be graded for guiding spills away from process equipment. Pumps handling hydrocarbons above the temperature of o 230 C or C4 and Lighters should not be installed underneath the air fin coolers. Tall towers requiring frequent operating attention at upper levels may be located at one place so that common connecting platform can be provided. (s) Stairways should be provided for the main access. Compressor house should be located near the battery limits to facilitate ease in maintenance and operation. The cabin should be for minimum occupancy of the shift operators of the respective facilities only.0 of this standard. The rest of controls should be taken to control room. Gas compressors should have roofing and open from sides to avoid accumulation of heavier vapours/gases on the floor of compressor house. Adequate drainage should be provided around such vessels. 6. Equipment spacing within the process unit may be varied to meet the requirements specified by Licensors or of the Engineering Consultants.000 cum. However in case these tanks are provided with windows opening on the shell and these windows will not get blocked in any case. Excluded petroleum shall be stored in a separate dyked enclosure and shall not be stored along with Class-A. Grouping of petroleum products for storage shall be based on the product classification. The minimum height of dyke wall in case of excluded petroleum shall be 600 mm. Tanks shall be arranged in maximum two rows so that each tank is approachable from the road surrounding the enclosure. Separation distances between the nearest tanks located in separate dykes shall not be less than the diameter of the larger of the two tanks or 30 meters. (g) 7.6meter wide flat section on top for stability of the dyke wall.0 m above average inside grade level. then it shall be treated as a group of fixed roof tanks for the purpose of above limits. concrete or solid masonry shall be designed to withstand the hydrostatic load. Aggregate capacity of tanks located in one dyked enclosure shall not exceed following values: • 60. (d) (e) (f) (a) Petroleum storage tanks shall be located in dyked enclosures with roads all around the enclosure.2 Equipment spacing with in process units. A free board of 200 mm above the calculated liquid level shall be considered for fixing the height of the dyke.0 m and shall not be more than 2.2 (a) (b) (c) 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. If a group of tanks contains both fixed and floating roof tanks. However. (b) Dyked enclosure shall be able to contain the complete contents of the largest tank in the dyke in case of any emergency. Earthen dyke wall shall have not less than 0.1 LAYOUT OF STORAGE TANKS General considerations Dyked Enclosures. Grouping. 7. where Class-C petroleum is stored in a common dyke along with Class-A and/or Class-B petroleum.0 7.000 cum. • 120. The height of tank enclosure dyke (including free board) shall be at least 1.' . Class-B or Class-C petroleum. the capacity of the dyked enclosure should be based on spill containment and not for containment on tank rupture.OISD-STD-118 7 -------------------------------------------------------------------------------------------------------------------------------------- (u) Equipment should be spaced to permit use of mobile equipment and power tools or servicing and maintaining equipment during turn around periods. Pump stations and piping manifold should be located outside dyke areas by the side of roads. all safety stipulations applicable for Class-A and/ or Class-B respectively shall apply. Class-C petroleum should preferably be stored in separate enclosure. For excluded petroleum. the distances specified in notes to Table-2 shall be met. However. Class-A and / or Class-B petroleum may be stored in the samedyked enclosure. The dyke wall made up of earth.1. for a group of floating roof tanks Fixed cum floating roof tanks shall be treated as fixed roof tanks. (c) Minimum separation distances between various equipment within process units are given in Table-2. whichever is more. Enclosure capacity shall be calculated after deducting the volume of tanks (other than the largest tank) and the tank pads within the dyke upto the height of the enclosure. The distances recommended should be followed to the extent feasible. for a group of fixed roof tanks. then these may be considered as floating roof tanks. This stipulation need not be applied to tanks storing excluded petroleum class. Process equipment should not be located inside the dyke.1. Tanks located overhead shall meet safety distances and shall also have dyked enclosure of RCC construction and provided with efficient drainage system for the dyke enclosure.1 7. Piping connected to tanks should run directly to outside of dyke to the extent possible to minimise piping within the enclosures. Storage vessels shall be laid out in single row both in case of the spheres and bullets. 7. LPG storage vessels shall not be located within the same dykes where other liquid hydrocarbons are stored. Table-5 shall also be applicable for the installation storing only Class-C petroleum. for Class-A and Class-B petroleum products is more than 5000 cum or the diameter of Class-A or Class-B product tank is more than 9 meters.3 and Table-4. Storage vessels shall not be stacked one above the other.2 Separation Distances between tanks / offsites facilities. (c) Excluded petroleum should be treated as Class-C petroleum for the purpose of separation distances and Table – 5 shall be applicable for their separation distances. 7. (b) A group of small tanks each not exceeding 9 meters in diameter and in all not exceeding 5. The following stipulations shall apply for the separation distances for above ground tanks storing petroleum: (a) For larger installation. Longitudinal axes of horizontal vessels (Bullets) should not point towards other vessels. Each group shall be provided with a curb wall. This table is applicable where total storage capacity of Class-A & Class-B is less than 5000 cum and diameter of any tank storing Class-A and Class-B petroleum product does not exceed 9 meters.' . shall be as per Oil Mines Regulations Piping from / to any tank located in a dyked enclosure should not pass through any other dyked enclosure.1.000 cum whichever is lower.3 Fire walls.4 (a) (b) (b) (c) (d) (c) The minimum distance between a tank shell and the inside toe of the dyke wall shall not be less than half the height of the tank.0 8. (d) There shall be access on all four sides of each dyke area and roads should be linked to minimize the effect if one road is cut off during the fire. (a) In a dyked enclosure where more than one tank is located. vital process equipments and control room. For the installations covered under Oil Mines Regulation. Capacity of each group shall be limited to 15000 cum. General.000 cum in capacity shall be treated as one tank for the provision of firewall. 8. firewall of height not less than 300 mm shall be provided by limiting the number of tanks to 10 or the capacity of group of tanks to 5.000 cum capacity and above shall be laid in single row.1. refer OISD-STD-150. Storage vessels should be located down wind of process units. (a) Vessels shall be arranged into groups each having a maximum of six vessels.1 7. (c) For excluded petroleum product storage. The requirements given below are applicable to above ground LPG storage facilities. important buildings and facilities. firewalls of minimum height 600mm shall be provided to prevent spills from one tank endangering any other tank in the same enclosure. For mounded LPG storage.1 8. dyke requirements etc.OISD-STD-118 8 -------------------------------------------------------------------------------------------------------------------------------------- Tanks having 50. The tables are applicable where total storage capacity (e) (f) (g) 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. (b) For smaller installation. Any vessel in one group shall be separated from a vessel in another group by a minimum distance of 30 meters. LAYOUT OF LPG FACILITIES General Considerations: LPG Storage. the maximum height of the tank. Spheres and bullets shall be treated as separate groups with 30 meters separation distance between two groups. minimum separation distances shall be as specified in Table-5.1. minimum separation distances shall be as specified in Table. The tank height shall not exceed one and half times the diameter of the tank or 20 m whichever is less. (c) 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. Full rake loading / unloading is shall be done on two separate rail gantries having a minimum distance of 50m.1. LPG bottling facilities should be located at a safe distance from other facilities with minimum ingress to trucking traffic and downwind to storage. Cylinders shall be stacked vertically.OISD-STD-118 9 -------------------------------------------------------------------------------------------------------------------------------------- (h) Spillage collection shallow sump shall be located at a distance where the flames from sump fire will not impinge on the vessel. Rail loading/unloading of LPG should be restricted to a maximum of half rake. For mounded LPG storage. refer OISDSTD-150.2 LPG (i) Minimum separation distances for above ground LPG facilities shall be as given in Table-6 & Table-7. The capacity of the collection sump shall be as per OISD-STD–144. Curb wall around the storage tank shall have a minimum height of 30cm.2 LPG bottling facility. Filling machines and testing facilities shall be organized in sequential manner distinctly in a separate area.3 (a) LPG truck loading/unloading gantry shall be located in a separate block and shall not be grouped with other petroleum products. distances for 8. Separation facilities. There shall not be any deep ditches in the surrounding area to avoid LPG settling. However it shall not exceed 60cm at shallow sump position. The bay should be designed in such a way that the driver's cabin will be facing the exit direction and shall have no obstruction. Trucking traffic shall be smooth to avoid blocking/ obstruction for loading and unloading of cylinders. For other details refer OISD-STD-144. 8. Stacking areas for empty and filled cylinders should be located separately. Bulk handling facilities.1.' . as otherwise evaporation of spilled LPG may get affected. This distance shall not be less than the diameter of the nearest vessel or 15 meters whichever is higher. (a) (b) (c) (d) (e) 8. Filled LPG cylinders shall not be stored in the vicinity of cylinders containing other gases or hazardous substances. Maximum number of LPG tank truck bays shall be restricted to 8 in one group. (b) LPG rail loading/unloading gantry shall be located on a separate rail spur and shall not be grouped with other petroleum products. maintenance and inspection of Terminal and Tank facilities. OISD-STD-106 on Process Design and Operating Philosophies on Relief and Disposal System. 8. OISD-STD. OISD-STD-116 on Fire protection Facilities for Petroleum Refineries / Process Plants 6. NFPA 30. The Static and Mobile Pressure Vessels (Unfired) Rules. Rules . flammable and Combustible Liquid Code. API Standard 2610–Design. construction. 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. 5.OISD-STD-118 10 -------------------------------------------------------------------------------------------------------------------------------------- 9.144 on LPG bottling plant and layouts. 9.0 REFERENCES: 1.' . 1981 3. Regulations . operation. The Petroleum 2. OISD-STD –117 on Fire protection facilities for Petroleum depots and terminals 7. 11.1984 Oil Mines Safety 4.2002. Fire 10. API Recommended Practices 2001– protection in Refineries. Loss Prevention in process Industries by Frank P Lees. API Separators / Oil sludge pit 1 Note-1 Note-3 30 30 30 60 90 45 45 60 45 30 60 60 30 90 2 Note-3 x 3 30 Note-4 4 30 Note-5 Note-6 Note-6 Note-6 30 90 30 30 60 (90) 30 T3 30 30 50 5 30 30 Note-6 Note-6 Note-6 30 90 30 30 60 (90) 30 T3 30 30 50 6 60 60 30 30 30 T7 90 30 T6 90 (90) 30 T7 45 30 60 7 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 8 45 45 30 30 30 30 90 Note-8 Note-9 60 30 Note-10 T3 60 30 50 9 45 45 30 30 30 T6 90 Note-9 T6 90 (90) T6 T6 60 30 50 10 60 30 60 60 60 90 90 60 90 x 30 30 12 12 30 90 11 45 Note-3 (90) (90) (90) (90) 90 30 (90) 30 x 15 50 30 30 Note-12 12 30 x 30 30 30 30 90 Note-10 T6 30 15 x 30 6 15 50 13 60 30 T3 T3 T3 T7 90 T3 T6 12 50 30 x 6 30 50 14 60 15 60 30 30 45 90 60 60 12 30 6 6 x 30 50 15 30 30 30 30 30 30 90 30 30 30 30 15 30 30 x 15 TABLE – 1 16 90 30 50 50 50 60 90 50 50 90 Note12 50 50 50 15 x Note-4 Note-6 Note -5 Note-6 30 60 90 45 45 30 Note-3 x 30 15 30 30 Note-6 30 90 30 30 60 (90) 30 T3 60 30 50 General Notes to Table-1 . 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.' .SEPARATION DISTANCES BETWEEN BLOCKS/FACILITIES Sr no 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 From / To Process Units Process Control Room (Note –2) Storage Tanks Class-A Storage Tank Class-B Storage Tank Class-C Pressurised Storage: LPG/ C4 & Lighter / H2 Flare (Note-7) Bulk Loading POL (Rail /Road) Bulk Loading LPG (Rail /Road) Fire Station / First Aid Center Boiler house / Process Unit Heaters (Note-11) Rail Spur Boundary wall around installation Service buildings Cooling tower. This shall be 36 meters considering the 6-meter wide road passing through the center. For Gas processing plants. whichever is more. heater of a process unit remains an integral part of the process unit to which it is attached and in that case the inter equipment distances should be inline with Table –2. Process control room to Process units / boiler house / heaters the minimum separation distance shall be 30 m. For distances within a dyke. For ground flare. the minimum separation distance shall be 30 meter. For Exploration & Production installations. Shall be 45 m for non-blast construction and 30 m for blast resistant construction. However. (ii) The distances given in the brackets ( ) are from the shell of the Heater / Boiler / Furnace / Still. The separation distance shall be 50 m. However. Separation distance between tank truck gantry and rail spur shall be 50 m. All distances shall be measured between the nearest points on the perimeter of each facility except (i) In case of tank vehicle loading / unloading area where the distance shall be from the center of nearest bay. the minimum separation distance shall be 16 m. Specific notes to Table-1: Note-1: Note-2: Note-3: Note-4: Note-5: Note-6: Note-7 Note-8 Note-9 Note-10 Note-11: Note-12: SEPARATION DISTANCES BETWEEN EQUIPMENT WITHIN PROCESS UNIT TABLE-2 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. these distances shall be 150 m. However for LPG tank truck bulk loading to POL tank truck bulk loading it shall be 30 m. “T” indicates the table number to be referred. it shall be as per Table-3 and Table-4 The distances specified are for the elevated flare. Type of construction shall be as per OISD-STD-163.' . “x” means any distance suitable for constructional or operational convenience.a) b) All distances are in meters. this shall be in line with Oil Mines Regulations Separation distance between Tank truck gantry and wagon gantry shall be 50m. Corrugated Plate Interceptor (CPI). For a control room attached to single process unit or a boiler or a heater. if these are covered from the top and provided with adequate venting to safe location. The edge of the road shall not be less than 15 meters away from the edge of the unit. open oil separators shall be categorized under the same risk and shall be located at a distance of 90 meters from heaters / boilers. Boiler house or heater of a process unit is to be treated as a separate identity only for the consideration of surrounding blocks / facilities. Centralized / common API separators. it shall be minimum 30 meters irrespective of whether it is for one or more units. Separation distances between the nearest tanks located in two dykes shall be equivalent to the diameter of the larger tank or 30 m. Shall be 60 m for non-blast construction and 30 m for blast resistant construction. for all other Hydrocarbons Heat Exchangers Air fin coolers for Hydrocarbons Fired heater Local control panel Pressure vessels / Drums of Hydrocarbons Main Pipe rack Blow down facility – Drum. pump.A & all above Auto-ignition temp Pumps . vent stack Structural main – Technological platforms 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 x 15 15 15 22 15 15 20 15 15 15 x 18 6 30 15 15 2 2 6 8 7 15 7 7 4 3 15 5 3 15 3 15 2 3 4 7 5 15 5 5 2 3 15 3 3 15 3 15 6 4 2 8 5 15 4 4 2 3 15 3 3 15 3 22 8 7 8 3 7 15 7 7 7 7 15 4 3 20 7 15 7 5 5 7 1 7 1 1 2 2 15 3 x 15 x 15 15 15 15 15 7 T-5 15 15 15 15 15 15 x 15 15 20 7 5 4 7 1 15 1 1 2 2 15 3 x 15 x 15 7 5 4 7 1 15 1 1 2 2 15 3 x 15 x 15 4 2 2 7 2 15 2 2 2 2 15 2 2 15 x 15 3 3 3 7 2 15 2 2 2 x 15 2 x 15 2 x 15 15 15 15 15 15 15 15 15 15 x 10 x 15 5 18 5 3 3 4 3 15 3 3 2 2 10 2 3 15 2 6 3 3 3 3 x x x x 2 x x 3 x 15 x 30 15 15 15 20 15 15 15 15 15 15 15 15 15 x 15 15 3 3 3 7 x 15 x x x 2 5 2 x 15 x General notes to Table –2: 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.' .Sr no 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 From / To Fired Heater / Any fired equipment Reactors Distillation column Accumulators – Hydrocarbons Compressors Hydrocarbons Hot oil pump Fuel Oil / HCs day tank Pumps for class. If the blow down drum is located underground / oil catcher is cover with vent to safe location. Distances specified in Table-2 are the minimum recommended distances that the industry should adhere. These could be suitably modified as required to suit space constraints and relevant engineering practices except the followings.3 7 8 9 1 2 3 4 5 6 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices. pump connected directly with the Fuel Oil system. (ii) d) e) f) g) Firewater hydrant / monitors shall be minimum 15 m away from the equipment that is to be protected. Fuel gas knock out drum shall be located at a minimum separation distance of 15 m from the heater. Separation distances specified in other OISD standards or elsewhere in this standard (other than Table –2) shall be followed as recommended. Fuel Oil day tank shall be located at a distance of not less than 15m from equipment except those facilities such as heat exchanger. operational and maintenance requirements.(For large installations) Tanks / Facility TABLE . the minimum separation distance shall be 15m.' . (i) Blow down facility (open pit type) / oil catcher shall be located at a distance not less than 30 m from fired heater / any fired equipment. “x” indicates suitable distance as per good engineering practices to meet construction. Water spray deluge valve shall be minimum 15 m from equipment handling hydrocarbon.a) b) c) All distances are face-to-face clear minimum distances in meters. SEPARATION DISTANCES BETWEEN TANK / OFFSITE FACILITIES . 5 D Min 20 m 0. Storage Tank for Petroleum Class C Storage / Filling Shed for petroleum Class A or class B Storage / Filling Shed for Petroleum Class C Tank vehicle loading / Unloading for petroleum class A or class B Tank Vehicle loading / unloading for Class C Flame proof Electric Motor Non flame proof electric Motor Boundary wall T4 T4 15 15 15 15 8 15 0.5 D Min 20 m 15 10 20 10 x x x 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.1 2 3 4 5 6 7 8 9 Storage Tank for Petroleum Class A / Class B.5 D Min 20 m T4 x 15 x 15 x x x 0.' .5 D Min 20 m 15 15 x 8 15 15 8 15 15 15 x 8 x 8 x x x 10 15 8 15 8 x x 8 15 20 15 x 15 x x x x x 10 8 x 8 x 8 x x 8 x 15 x 15 x 15 x 8 x x 0. (For small installations) TABLE – 5 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.3. the stringent of the applicable formulae shall be considered for minimum separation distance. Distances given are shell to shell in the same dyke. e) In Table –4. Between floating Roof Tanks Class A & B Between fixed Roof Tanks Class A &B TABLE– 4 Between Class C Petroleum Storage tanks (D+d) / 4 Min 10 m (D+d) / 4 (D+d) / 4 Min 10 m (D+d) / 3 (D+d) / 6 Min 6 m (D+d) / 4 General notes to Table – 3 & 4 a) All distances are in meters. g) The distance of storage tanks from boundary wall is applicable for. b) “x” indicates suitable distance as per good engineering practices to meet construction. (i) (ii) Floating roof tanks having protection for exposure Tanks with weak roof-to-shell joint having approved foam or inerting system and the tank diameter not exceeding 50 meters h) For the facilities not covered in Table. refer Table-1. d) In Table – 3 all distances shall be measured between the nearest points on the perimeter of each facility except in the case of tank vehicle loading/unloading area where the distance shall be measured from the center of each bay. operational and maintenance requirements c) D & d stands for diameter of larger and smaller tanks. SEPARATION DISTANCES BETWEEN TANKS/OFFSITE FACILITIES . f)For different combination of storage tanks.SEPARATION DISTANCES BETWEEN STORAGE TANKS WITHIN A DYKE Item 1 2 All tanks with Diameter upto 50 meters Tanks with Diameter exceeding 50 meters.' . 5 4.5 x x x 3 3 10 3 3 x 3 1.0 4 9 9 9 x 4.5D Min 3.5 D Min 4.5 6 9 9 9 3 9 9 9 5 9 0.5D 0.5 x 9 4.5 x 9 4.5 3 9 4.5D 0.5 D Min 4.5D / 6.5 x x 3 x x 11 15 4.5 3 0.5 4.5 3 x x x x 13 15 D Min 4.5 4.0 x 9 0.B Tank vehicle Loading / unloading Class .5 0.0 0.5 x 1.5D 9 4.0 9 4.5 4.5 1.0 0.5 x 9 4.5 4. stores.5D / 6.5D Min 3.5 D Min 3.5 4.5 3 9 4.A Tank vehicle Loading / unloading Class .5 9 x 4.5 x 9 4.5 x 9 4.0 9 0.5 x x x 0.5D / 6.5 4.' .1 1 2 3 4 5 6 7 8 9 10 11 12 13 Storage Tank Class A Storage Tank Class B Storage Tank Class C Storage / Filling shed for petroleum Class -A Storage / Filling shed for petroleum Class -B Storage / Filling shed for petroleum Class -C Tank vehicle Loading / unloading Class .5D x 9 4.5 9 4.5 x 3 x x x 12 15 D Min 4.5 9 4.5 x 3 1.5D 0.5D / 6.5 4.5 3 4.5D x 6 1.5 4.C Flame proof Electric motors Non Flame proof Electric motors Office building. amenities Boundary wall 0.0 9 9 9 15 15 15 3 15 15 15 2 0.5 6 9 0.5 9 15 4.5D 0.5 4.5 x x x 3 3 7 15 9 9 9 9 9 x 9 9 3 9 9 9 8 15 4.5 3 x x x x General notes to Table –5: 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.5D 0.5D 4.5D Min 3.5 1.5 0.5D 0.0 9 4. operational and maintenance requirements “D” indicates the diameter of the larger tank. the minimum thereof shall be used. All distances shall be measured between the nearest points on the perimeter of each facility except in case of tank vehicle loading /unloading area where the distance shall be from the center of each bay. SEPARATION DISTANCES FOR LPG FACILITIES TABLE . “x” indicates suitable distance as per good engineering practices to meet construction.a) b) c) d) e) f) g) All distances are in meter and the table specifies the minimum requirement.0).5 D / 6.6 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.' . Distances given for the tanks are shell to shell in the same dyke. Where alternate distances are specified (like 0. Pig launcher/receiver at liquid hydrocarbon handling pipeline installations should be located at least 5 m from boundary. Cylinder evacuation facilities Tank Truck Loading / unloading gantry Tank wagon gantry Rail spur Pump house / Compressor house (LPG) Fire Water pump house 1 2 3 4 5 6 7 8 Note-1 T7 30 30 50 30 15 60 T7 x 30 30 50 30 30 x 30 30 15 30 50 30 15 60 30 30 30 30 50 50 30 60 50 50 50 50 50 50 30 60 30 30 30 50 50 50 30 60 15 30 15 30 30 30 x 60 60 x 60 60 60 60 60 x TABLE– 7 SEPARATION DISTANCES BETWEEN LPG STORAGE VESSELS AND BOUNDARY WALL / GROUP OF BUILDINGS NOT ASSOCIATED WITH LPG FACILITIES 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.' .Sr no. 1 2 3 4 5 6 7 8 FROM / TO LPG Storage vessels Boundary wall / group of buildings not associated with LPG plant Shed for filling and storage of LPG. Cold repair shed. 3800 90 General Notes to Table-6 & Table-7.450 40 451-750 60 751 .20 15 21 .Capacity of Each vessel in Cum of water Distance in meters 10 . Specific Notes to Table. operational and maintenance requirements d) T7 indicates Table –7.40 20 41 . e) Distance of stabling line shall be as per Railway Standards. b) All distances are in meters c) “x “indicates suitable distance as per good engineering practices to meet construction.' . a) Table-6 is applicable for total storage of above 100 Tonnes. 'OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting from use of the OISD Standards/ Guidelines/ Recommended Practices.6.350 30 351 . Note–1: The distance shall be 2 meters or 1/4 of the sum of the diameters of the adjacent vessels or half the diameter of the larger of the two adjacent vessels in the same group whichever is greater.